Capability Statement

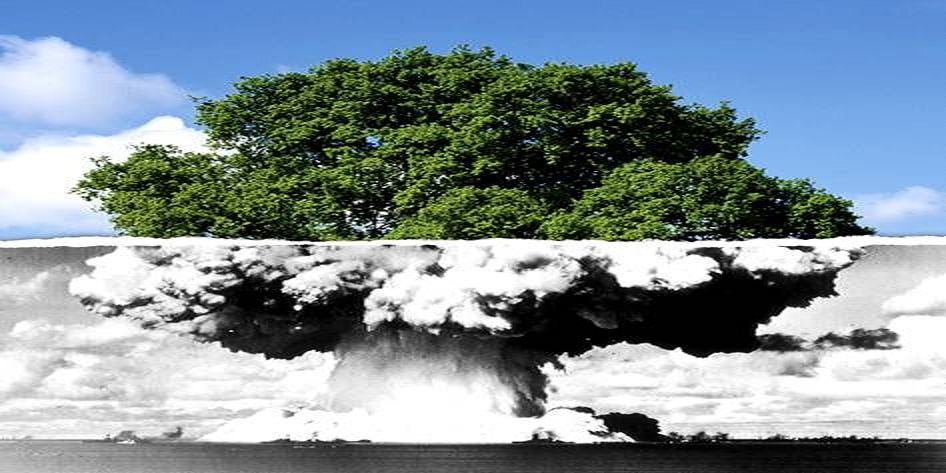

SGS Minerals Services has worked successfully on Canadian uranium projects for over half a century. Since our inception during World War 2, we’ve been the lab of choice for Canadian uranium work. Throughout this time, we have developed the expertise as well as the stringent safety infrastructure required for working with uranium.

SGS Minerals Services experienced metallurgical professionals and technicians provide bankable results for your uranium project. Processes that SGS Minerals Services offers for uranium include:

· Sample preparation

· Laboratory analysis

· Froth flotation

· Gravity separation

· Precipitation

· Roasting

· Solvent extraction

· Ion exchange

· Leaching

Uranium Processing

The optimum flowsheet for the extraction of uranium is dependent on the ore type and also the uranium and gangue mineralogy within the deposit.

The Process

Ore Preparation

Ore preparation usually consists of some form of crushing, grinding, screening and/or classification. The following equipment is typically used for this:

· Jaw and cone crushers

· Batch and pilot rod mills

· Batch and pilot ball mills

· Cyclones

· Screens

Pre-concentration

Magnetic separation equipment consists of wet and dry rolls, a batch (ferrous wheel) separator which uses permanent magnets, and a custom-built WHIMS (wet high intensity magnetic separator) machine. Other magnetic equipment can be obtained from suppliers by special arrangement. A Davis tube separator is available for assessing the magnetic content of samples.

Gravity concentration equipment consists of shaking tables, centrifugal separators, jigs of various sizes, dense medium separators and a spiral rig where a range of spirals can be evaluated.

Magnetic separation equipment consists of wet and dry rolls, a batch (ferrous wheel) separator which uses permanent magnets, and a custom-built WHIMS (wet high intensity magnetic separator) machine. Other magnetic equipment can be obtained from suppliers by special arrangement. A Davis tube separator is available for assessing the magnetic content of samples.

Gravity concentration equipment consists of shaking tables, centrifugal separators, jigs of various sizes, dense medium separators and a spiral rig where a range of spirals can be evaluated.

Roasting

· Small-scale roasts can be conducted in a muffle furnace to 1,300ºC

· Larger scale batch roasting (up to 500) can be conducted in a rotary kiln to 1,400ºC, the gaseous atmosphere can be accurately controlled

· A pilot-scale kiln is available for specific campaigns

Leaching and Precipitation

SGS Minerals Services has extensive leaching experience ranging from simple batch leaching and column leaching, though to complex pressure acid leaching pilot plant campaigns.

SGS Minerals Services has extensive leaching experience ranging from simple batch leaching and column leaching, though to complex pressure acid leaching pilot plant campaigns.

· Batch leaching can be conducted in shake flasks or agitated tanks under controlled conditions.

· Continuous leaching can be done in a number of pilot configurations using the tankage and solid/liquid separation equipment available.

· A number of precipitation reactors are available

Solvent Extraction

SGS Minerals Services has conducted extensive solvent extraction testwork over the past three years, ranging from simple batch shakeout tests to extended operation of a complex integrated SX/EW circuit. Much of this work has focused on nickel, cobalt and copper, while our Australian facility has conducted SX tests on vanadium, including pilot plant operation. In this process, vanadium was leached in sulphuric acid and extracted using D2EHPA to finally produce vanadium pentoxide as a product. This process is very similar to uranium extraction.

A range of mixer-settler sizes is available for batch and continuous pilot testing.

SGS Minerals Services has conducted extensive solvent extraction testwork over the past three years, ranging from simple batch shakeout tests to extended operation of a complex integrated SX/EW circuit. Much of this work has focused on nickel, cobalt and copper, while our Australian facility has conducted SX tests on vanadium, including pilot plant operation. In this process, vanadium was leached in sulphuric acid and extracted using D2EHPA to finally produce vanadium pentoxide as a product. This process is very similar to uranium extraction.

A range of mixer-settler sizes is available for batch and continuous pilot testing.

0 comments:

Post a Comment