The Nuclear Fuel Cycle | |

Like coal, oil and natural gas, uranium is an energy resource which must be processed through a series of steps to produce an efficient fuel for use in the generation of electricity. Each fuel has its own distinctive fuel cycle: however the uranium or 'nuclear fuel cycle' is more complex than the others. To prepare uranium for use in a nuclear reactor, it undergoes the steps of mining and milling, conversion, enrichment and fuel fabrication. These steps make up the 'front end' of the nuclear fuel cycle. After uranium has been used in a reactor to produce electricity it is known as 'spent fuel' and may undergo a further series of steps including temporary storage, reprocessing, and recycling before eventual disposal as waste. Collectively these steps are known as the 'back end' of the fuel cycle. These are the various steps that together make up the entire Nuclear Fuel Cycle: |  |

Mining and milling | |

Uranium is usually mined by either surface (open cut) or underground mining techniques, depending on the depth at which the ore body is found. From these, the mined uranium ore is sent to a mill which is usually located close to the mine. At the mill the ore is crushed and ground to a fine slurry which is leached in sulfuric acid to allow the separation of uranium from the waste rock. It is then recovered from solution and precipitated as uranium oxide (U308) concentrate.* *Sometimes this is known as "yellowcake", though it is finally khaki in colour. U308 is the uranium product which is sold. About 200 tonnes is required to keep a large (1000 MWe) nuclear power reactor generating electricity for one year. | |

Conversion | |

Because uranium needs to be in the form of a gas before it can be enriched, the U308 is converted into the gas uranium hexafluoride (UF6) at a conversion plant in Europe, Russia or North America. | |

Enrichment | |

The vast majority of all nuclear power reactors in operation and under construction require 'enriched' uranium fuel in which the proportion of the U-235 isotope has been raised from the natural level of 0.7% to about 3.5% or slightly more. In natural Uranium for every 235U atom there is 140 238U atoms. |  |

The enrichment process by centrifuge removes about 85% of the U-238 by separating gaseous uranium hexafluoride into two streams: One stream is enriched to the required level and then passes to the next stage of the fuel cycle. The other stream is depleted in U-235 and is called tails. It is mostly U-238. |  |

The figures in the diagram assume enrichment by centrifuge to 3.5% U-235 and a tails assay of 0.25%. So little U-235 remains in the tails (usually less than 0.25%) that it is of no further use for energy, though such 'depleted uranium' is used in metal form in yacht keels, as counterweights, and as radiation shielding, since it is 1.7 times denser than lead. The first enrichment plants were built in the USA and used the gaseous diffusion process, but more modern plants in Europe and Russia use the centrifuge process. This has the advantage of using much less power per unit of enrichment and can be built in smaller, more economic units. Research is being conducted into laser enrichment, which appears to be a promising new technology. A small number of reactors, notably the Canadian CANDU and early British gas-cooled reactors, do not require uranium to be enriched. | |

Fuel fabrication | |

Enriched UF6 is transported to a fuel fabrication plant where it is converted to uranium dioxide (UO2) powder and pressed into small pellets. These pellets are inserted into thin tubes, usually of a zirconium alloy (zircalloy) or stainless steel, to form fuel rods. The rods are then sealed and assembled in clusters to form fuel assemblies for use in the core of the nuclear reactor. Some 25 tonnes of fresh fuel is required each year by a 1000 MWe reactor. |   |

The nuclear reactor | |

Several hundred fuel assemblies make up the core of a reactor. For a reactor with an output of 1000 megawatts (MWe), the core would contain about 75 tonnes of low-enriched uranium. In the reactor core the U-235 isotope fissions or splits, producing heat in a continuous process is called a chain reaction. The process depends on the presence of a moderator such as water or graphite, and is fully controlled. Some of the U-238 in the reactor core is turned into plutonium and about half of this is also fissioned, providing about one third of the reactor's energy output. | |

As in fossil-fuel burning electricity generating plants, the heat is used to produce steam to drive a turbine and an electric generator, in this case producing about 7 billion kilowatt hours of electricity in one year. To maintain efficient reactor performance, about one-third of the spent fuel is removed every year or 18 months, to be replaced with fresh fuel. | |

Spent fuel storage | |

Spent fuel assemblies taken from the reactor core are highly radioactive and give off a lot of heat. They are therefore stored in special ponds which are usually located at the reactor site, to allow both their heat and radioactivity to decrease. The water in the ponds serves the dual purpose of acting as a barrier against radiation and dispersing the heat from the spent fuel. | |

Spent fuel can be stored safely in storage ponds for long periods. It can also be dry stored in engineered facilities, cooled by air. However, both kinds of storage are intended only as transient step before the spent fuel is either reprocessed or sent to final disposal. The longer it is stored, the easier it is to handle, due to decay of radioactivity. There are two alternatives for spent fuel:

|  |

Reprocessing | |

Spent fuel still contains approximately 96% of its original uranium, of which the fissionable U-235 content has been reduced to less than 1%. About 3% of spent fuel comprises waste products and the remaining 1% is plutonium (Pu) produced while the fuel was in the reactor and not "burned" then, according to the following reactions 23892U + n ---- β- ----> 23992U ---- β- ----> 239Np ----- β- -----> 23994Pu. Reprocessing separates uranium and plutonium from waste products (and from the fuel assembly cladding) by chopping up the fuel rods and dissolving them in acid to separate the various materials. Recovered uranium can be returned to the conversion plant for conversion to uranium hexafluoride and subsequent re-enrichment. The reactor-grade plutonium can be blended with enriched uranium to produce a mixed oxide (MOX) fuel*, in a fuel fabrication plant. |  |

Vitrification | |

After reprocessing the liquid high-level waste can be calcined (heated strongly) to produce a dry powder which is incorporated into borosilicate (Pyrex) glass to immobilise the waste. The glass is then poured into stainless steel canisters, each holding 400 kg of glass. A year's waste from a 1000 MWe reactor is contained in 5 tonnes of such glass, or about 12 canisters 1.3 metres high and 0.4 metres in diameter. These can be readily transported and stored, with appropriate shielding. This is as far as the nuclear fuel cycle goes at present. The final disposal of vitrified high-level wastes, or the final disposal of spent fuel which has not been reprocessed spent fuel, has not yet taken place. | |

Final disposal | |

The waste forms envisaged for disposal are vitrified high-level wastes sealed into stainless steel canisters, or spent fuel rods encapsulated in corrosion-resistant metals such as copper or stainless steel. The most widely accepted plans are for these to be buried in stable rock structures deep underground. Many geological formations such as granite, volcanic tuff, salt or shale will be suitable. The first permanent disposal is expected to occur about 2010. |  |

Most countries intend to introduce final disposal sometime after about 2010, when the quantities to be disposed of will be sufficient to make it economically justifiable. | |

Keeping the fuel cycle civil | |

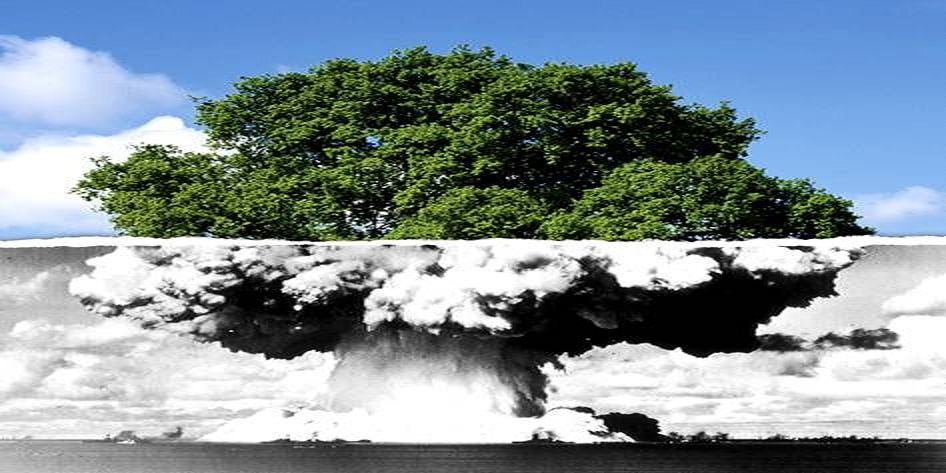

Much of the civil nuclear fuel cycle evolved half a century ago from military programs and from naval use of reactors to power warships, particularly submarines. Ever since then the prospect of wider use of nuclear energy for power generation has created a concern to ensure that this did not lead to the proliferation of nuclear weapons in countries which did not already have them. Safeguards are accounting and auditing procedures applied to all nuclear materials in NPT countries, so that when they are used or traded their civil use can be verified. It follows that uranium cannot be traded with any country which does not permit it to remain under NPT safeguards. Under the "Additional Protocol" some countries are now accepting "strengthened safeguards" under which IAEA inspectors probe more widely than simply known nuclear materials. The IAEA's goal is to win universal acceptance of the Additional Protocol. | |

India and Pakistan have agreed to IAEA safeguards on certain reactors, even though those countries are not signatories of the NPT. Certain countries comprising the Nuclear Suppliers' Group have entered into a non-treaty agreement not to engage in nuclear commerce (materials or equipment) with any country not a party to the NPT. The NPT is based on an agreement between the five main nuclear weapons states and the other countries interested in nuclear technology. The deal was that assistance and cooperation in developing nuclear power and related technologies would depend on pledges, backed by international security, that no plant or material would be diverted to weapons use. Those who refused to be part of the deal would be excluded from international cooperation or trade involving nuclear technology. | |

In addition to the NPT, Australia and Canada have systems of bilateral agreements with customer countries which further tighten the control of uranium which is supplied. These accounting systems follow uranium from when it is produced and packed for export, to the time it is reprocessed or stored as nuclear waste, anywhere in the world. They also include plutonium which is in the spent fuel. These systems operate in addition to safeguards applied by the IAEA which keep track of the movement of nuclear materials through fuel cycle facilities in other countries and which verify inventories. Total cost is thus about US$ 860 for 1 kg enriched fuel, plus about $240 for actual fuel fabrication. This will yield about 3900 GJ thermal energy at modern burn-up rates, or about 360,000 kWh of electricity (at 33% thermal efficiency), and does the same job as about 160 tonnes of steaming coal for a total cost of 0.31 cents/kWh (US$). | |

0 comments:

Post a Comment