We're back into business again!!! Yes, We’re interested to explain a bit about the Back End Process.

Enough with a lot of talk about “nuclear waste” and what should be done with it. Now, this it it. Again, The Back End. As we know that, there are different categories of radioactive waste which include everything from very low level material like contaminated lab coats and beakers from radiological tracers all the way up to highly concentrated high-energy radiation sources. Generally the majority of such waste is not especially difficult to deal with, as much of it is not actually very radioactive at all.

The material is “spent fuel” the uranium fuel rods from reactors which have been used for power generation and are no longer suitable for sustaining fission in typical reactors. This material is currently being stored on site by nuclear power plants. Much of it is in “spent fuel pools” where it is submerged in water for shielding and cooling. I think, maybe also we practiced the same at Triga Mark II Research Reactor at Nuclear Malaysia. Other, generally older, spent fuel is in “dry storage” in concrete or metal casks also primarily located on site at nuclear reactor locations. For example, in the US alone there are hundreds of thousands of metric tons of spent fuel in storage and nuclear plants and elsewhere. Even more is located at other sites worldwide.

The current plan in the US is to move the spent fuel by road and rail to the Yucca Mountain federal repository site in Nevada. But, nowadays The President of USA, Barrack Obama has given green light to shutdown the Yucca Mountain due to certain factors. But there, the spent fuel and other “waste” materials would be placed in tunnels, located deep within the rock of the mountain. Geological studies have been done in the area and the Department of Energy is confident that the materials could be safely entombed in the mountain for hundreds of thousands of years. The repository was supposed to begin accepting shipments in 1998, but due to opposition and delays it will probably not be fully operational for at least another decade.

Needless to say, this has been an issue which has garnered the attention of the eco-stupid movement. It has also been the subject of criticism on the pro-nuclear side. Many other countries manage their nuclear waste through reprocessing programs. In the US, all reprocessing activities ended by the Carter Administration. It was claimed that reprocessing of nuclear fuel could lead to proliferation of nuclear weapons. Apparently and ironically, Mr. Carter was not aware that the US already had thousands of tons of weapons-grade material stockpiles and tens of thousands of nuclear warheads already assembled, and therefore the recovery of added plutonium would not really change much, especially considering that reactor grade plutonium is not suitable for use in weapons. It is clearly stated that they are not taking this matter seriously.

Despite the fact that many seem to have opinions about what should be done with spent fuel and the fact that spent fuel “waste” is one of the biggest issues in the anti-nuclear movement, few seem to even know what the material is made of. So here’s the breakdown of what we’re dealing with. The amounts will vary depending on the type of reactor, but these numbers represent a typical lightwater power reactor, like those used in the US and around the world for electricity production:

Uranium: 94-96%

Basically the fuel that goes into a reactor starts off as uranium and when it comes out, it’s mostly still uranium. Natural uranium consists of about .7% uranium-235, which the remainder being almost entirely uranium-238. Since uranium-235 is the easily fissionable isotope, it’s concentration is increased through “enrichment” for use in reactors. When the fuel goes into a commercial nuclear reactor it is usually around 3% uranium-235. After being used, it contains about 0.9%-1.2% uranium-235, which has not been fissioned by the reactor. This is generally higher than natural uranium, making the material an even richer source of U-235 than natural uranium minerals.Other isotopes of uranium may be present in smaller quantities.

These include uranium-236, which forms when a U-235 atom captures a neutron but does not fission. U-236 may be in concentrations of about .4% or so. It’s not really very useful, as it does not fission easily and has a relatively low neutron cross section. With a half-life of a few million years, it’s a bit more radioactive than most other isotopes, but not radioactive enough to be considered much of a danger. If the uranium is recycled, the U-236 remains in the mix. It may be fissioned in a fast neutron reactor but otherwise is basically neither a resource nor a major problem.

Plutonium: 1%-2%

Now we discussed about plutonium. Plutonium is formed when uranium-238 captures a neutron and rapidly decays to neptunium-239 and then plutonium-239. All reactors produce some plutonium, although breeder reactor are designed especially to do so. Plutonium-239 has a half-life of 24,000 years and is a strong alpha emitter. Comparatively speaking, plutonium is not nearly as dangerous as many other radioisotopes, including some natural ones like radium-226. However, it can be quite toxic if it is ingested or inhaled and the longer half-life means that disposing of plutonium presents concerns about the long-term stability of a site.

But there’s another way to get rid of plutonium which can turn a waste product into an asset. Plutonium is fissionable and thus can be used as reactor fuel. It can be burned in a standard lightwater reactor in the form of mixed oxide fuel or it can be burned with even higher effeciency in a fast neutron reactor. This not only reduces material to be disposed of but increases the effeciency of the fuel cycle, possibly by up to 200 times, if all the avaliable energy is extracted by plutonium breeding and recovery.

One thing the plutonium from a standard power reactor is NOT suitable for, however is weaponry. This is because it contains too high a ratio of plutonium-240 to plutonium-239. Although plutonoum-240 is not a problem for reactors, it is a neutron emitter, which in a bomb, would cause the reaction to start too soon and the weapon to “fizzle” and fail. Weapons grade plutonium must contain at least 80% plutonium-239, but most reactor grade plutonium contains less than 70% plutonium-239.

It is theoretically possible to build a weapon from reactor grade plutonium and the possibility was demonstrated by nuclear experiments in the 1970’s, however doing so requires a highly efficient weapon design, is extremely unreliable and suffers from reduced yield. In general, such material is very difficult to weaponize and would probably not be worth the effort even when compared to construction of a purpose-built weapons grade breeder reactor.

Minor Actinides: Less than <1%

Minor Actinides are heavy elements other than uranium and plutonium which are the result of neutron capture, usually by plutonium which does not fission. They include neptunium, americium and curium. The amount present in spent fuel will vary but is higher in reactors which have high levels of plutonium. They generally have halflives of a few decades or more and are therefore somewhat hazardous, but only when highly concentrated. They are able to fission and can be used in standard thermal reactors, but they are more easily and efficiently fissioned in fast neutron reactors. In some cases, these isotopes are also useful in a concentrated form for use as a neutron source or for industrial radiation sources. Americium-241 is commonly used in industry as well as in smoke detectors. Californium isotopes such as Ca-252 are commonly used as neutron sources.

Fission Byproducts: About 3%

At this level, these are the materials which result from the actual fission of heavy element atoms. Each time a uranium or plutonium atom splits, it results in two new atoms. The new materials vary in type but tend to have an atomic mass around 80 to 100 or 130 to 150. A few of these are actually stable but most are radioactive and have varying half-lives. Fission products can be loosely categorized into three major groups:

Short-lived: The vast majority of fission products have relatively short half-lives of a year or less. These isotopes are highly radioactive and contribute to the vast majority of the radioactivity in freshly used fuel. They are quite hazardous and can can be dangerous to be exposed to even for a short period of time without shielding. However, they are not a disposal problem because of the short half life of the materials. Since the shortest lived isotopes are also the most radioactive, the spent fuel will rapidly loose most of its radioactivity and be less than 1% as radioactive after one year as it was to begin with. Simply allowing the spent fuel to decay for a period of a few years or more will eliminate these highly radioactive materials.

Medium-lived: These are the fissio n byproducts which have a half life of more than a year or two but less than centuries. These makeup about 10%-20% of the total fission byproduct yield. These can be something of a hazard, especially when highly concentrated. However, they still are long-lived enough that they require disposal of some type. Generally about 300 years is all that is needed to assure that they have been nearly eliminated from any waste material and the material is no longer any more hazardous than natural uranium ore. From a geological standpoint this is a very short period and it is not difficult to assure that a geological formation will remain stable for such periods of time.

These materials can also be destroyed by photoneutron transmutation or by bombardment with fast neutrons. However, the two isotopes which account for most of the medium-lived byproducts, strontium-90 and cesium-137, both have relatively small neutron capture cross-sections and strong binding energies. Because of this it is not generally considered to be worthwhile to transmutate these materials. When diluted and embeded into chemically inert materials, they are considered safe and will be similar to natural radioactive minerals in a relatively short period of time.

As far as i understand that the core concept of transmutation – which was formulated as early as mid 20th century – consists of irradiating the actinides by fast neutrons. The highly stimulated nuclei that are generated this way suffer a fission, which leads to relatively short-lived nuclei, which in turn rapidly disintegrate into stable isotopes. Then, they cease to be radioactive. Thus, the required radioactive waste isolation time of several millions years could be decreased to 300 and up to 500 years. The technological progress made in the last decades has made the transmutation possible at the industrial level.

An efficient transmutation of radioactive waste requires the development of new facilities. In addition to specially designed fast reactors, the Accelerator-Driven Systems (ADS) present a new potential concept. This is an undercritical reactor, which cannot sustain any chain reaction. The neutrons necessary for stationary operations are supplied by a proton accelerator with a spallation target located in the reactor core.

During the spallation, the atomic nuclei of the target (mainly lead) are broken with high-energy protons, while a large number of neutrons are normally released, neutrons which are necessary for the stationary operation of the reactor. If the accelerator is turned off, the chain reaction ceases. Worldwide studies are based on the assumption that at least two decades will be necessary to transfer this concept to the industrial level, a concept which is fully understood at the scientific level.

Long-Lived: These makeup about 20% of the total fission product yield and are the isotopes with half-lives of thousands or millions of years. They include technetium-99, iodine-129 and cesium-135. Because of the long half-lives they are not nearly as hazardous as other radioactive materials, but they will continue to be radioactive for a long period of time. It is important to note that they are on par with numerous natural radioactive materials such as potassium-40, which is quite common in any potassium-baring compound.

Most of these materials do have a sufficient neutron cross-section that they can be transmutation into shorter-lived isotopes by fast spectrum reactors. Therefore, irradiation of fuel by a fast spectrum reactor will have the net effect of reducing these materials, possibly by more than half. However, even without such treatment, disposal of such materials in chemically stable mediums does not present a hazard beyond that of natural radioactive minerals. Compared to uranium deposits, which contain radium-226 and polonium-210, such material is quite low in overall radiotoxicity, even in the short term. When combined with medium-lived fission products the immediate radiotoxicity is only marginally higher.

Disposal of such materials: In order to dispose of fission products which are long or medium lived, a few options exist. As mentioned, it is possible to destroy these materials and in some cases get surplus energy as a byproduct. This can be done by photoneutron transmutation, but the process has never been demonstrated on a full-scale system. Irridiation with fast neutrons of spent fuel can reduce the overall number of long-lived fission products, but because these products do not fission, a reactor with a high neutron economy is required. Even so, fast neutron irradiation is unlikely to completely eliminate fission products in spent fuel.

The most common method for disposal is in vitrified material. Vitrification is a process which produces which creates a solid, chemically inert material which is similar to a very high density glass. It is highly stable, is not easily reduced to a powder and is not soluble in water or nearly any other liquid. In general, the vitrified material is primary composed of non-radioactive materials which are used to help bind the radioisotopes. Thus, a few kilograms of radioactive material may be embedded in a cubic meter or more of vitrified material.

This means that the resulting material is not as radioactive as highly concentrated radioisotopes would be. It is similar in properties to some minerals and is sometimes referred to as “synthetic rock.” Disposal of short and medium lived fission products in such a manner will result in a material which is immediately of minimal hazard and which will be equivalent in overall radioactivity to numerous natural minerals in a period of about 300 years or less. It is important to note that it will be significantly less radioactive long before this, however, than it started out as.

The case for reprocessing vs geological disposal of the entire spent fuel material:

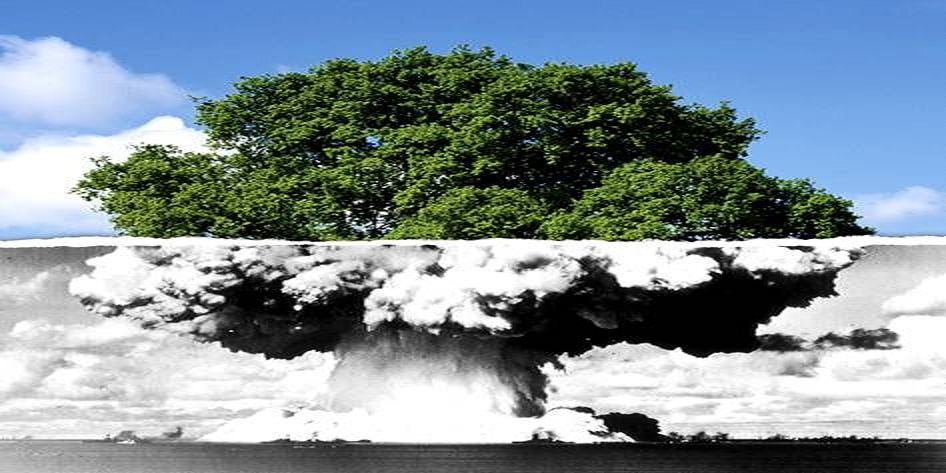

To sum up the composition of spent fuel, this somewhat simplified graph illustrates the relative nature of the materials contained within the spent fuel assemblies:

It should be obvious that disposing of the entire assemblies is both wasteful and unnecessary. There are several methods which can be used to effectively manage the material from spent fuel in a manner which is more efficient manner.

Reprocessing - This is the most obvious solution to the waste issue. Reprocessing involves separation of the material into it’s chemical components, thus recovering the uranium and plutonium for use in fabrication of new fuel. The remaining fission products can be vitrified as waste or could potentially be used for medical or industrial isotope needs, depending on the circumstances. There are a few issues which exist with reprocessing.

First, the process can be rather complicated and because of the possibility of contamination, it is necessary to have a well equipped and safe facility. This can involve an initially high investment. Also, although reprocessing does dramatically reduce high level waste, it does often produce additional intermediate level waste. This includes contaminated equipment and storage vessels. This waste is not really as much of a disposal hazard, but needs to be taken into account.

Despite the challenges, numerous examples exist of reprocessing programs which have proven to be both safe and beneficial to the overall fuel cycle. For example, in France a nation which gets nearly all of its electricity from nuclear energy has a long-running reprocessing and isolation program which has resultes in an annual production of high density vitrified waste of about 160 cubic meters.Considering the size of the country and standard of living, this is a very reasonable and small amount of material.

The traditional method of reprocessing is aqueous reprocessing, such as thePUREX process. Although it has been successfully used for decades, newer methods, such apyroprocessing, have demonstrated improved economics and could even be implemented onsite. Advanced reprocessing techniques can also reduce the possibility of secondary low-level waste.

Fast Neutron Reactors: The use of fast spectrum neutron reactors can greatly improve the effeciency of the nuclear fuel cycle as well as reduce overall waste. Fast reactors can be designed to breed fuel as fast as they burn it, thus allowing fuel rods to be used for much longer durations and thus reduce the volume of material to be processed.

They can also be designed to efficiently burn plutonium and other minor actinide. Irradiation by fast neutrons can also reduce the amounts of fission products like iodine-129 and technetium-99, converting both to much shorter lived isotopes. The use of a fast neutron reactor may be part of a reprocessing program or may be used in a program that does not involve such reprocessing. Some fast reactor designs allow for many years of operation on a single fuel cartridge and produce less radioactive waste by re-irradiating the depleted materials.

Accelerator-based Transmutation: This procedure has not been demonstrated in full scale, but holds the promise of treating spent fuel in a manner which will render it safe for normal disposal and produce energy in the process. Sub-critical reactors have been proposed as a means of transmutating waste with neutrons, although this would not work with all of the isotopes present, due to the low neutron cross section of some. Another method, which would theoretically be able to address all materials present without the necessity of reprocessing and producing energy in the process is photoneutron transmutation.

The company Nuclear Solutions has proposed a demonstration plant to transmutate nuclear waste using a 10MeV electron beam. Such a system would produce high energy gamma rays by secondary reactions, thus allowing for decomposition of radioactive atoms and production of surplus energy in the process.

Alternative Reactor Designs: While this would not be able to address the current spent fuel stockpiles alone, new reactor types can produce dramatically less waste and less hazardous waste. As mentioned, fast spectrum reactors can be used to destroy many of the long-lived radioisotopes, but other reactor designs can also have benefits in terms of waste produced. Higher effeciency reactors can burn the same fuel longer. This has been demonstrated by some advanced CANDU reactor designs.

Thorium-cycle systems produce virtually no plutonium or other actinides and thus have much less long-lived byproducts. Spent fuel from such designs would be only need a few centuries to decay to bellow natural material levels, even without reprocessing. Other designs allow for onsite reprocessing or easier spent fuel management.

Useful energy - Nowadays, the problem of radioactive waste is a global one, and getting increasingly worse. All countries in the industrialized world are waking up to the need for safer hazardous waste disposal methods. In my research recently for my FYP (Final Year Project), i have found that there is a firm named as Environmental Energy Resources (EER), has developed a reactor that converts radioactive, hazardous and municipal waste into inert byproducts; vitrified slag and clean energy.

Using a system called plasma gasification melting technology (PGM) developed by scientists from Russia's Kurchatov Institute research center, the Radon Institute in Russia, and Technion Institute - EER combines high temperatures and low-radioactive energy to transform waste into vitrified slag and syngas which is used to make electricity. The process will go up to 7,000 degrees centigrade and end at 1,400 centigrade.

The EER's waste disposal reactor does not harm the environment and leaves no surface water, groundwater, or soil pollution in its wake. The EER reactor combines three processes into one solution: it takes plasma torches to break down the waste; carbon leftovers are gasified and inorganic components are converted to solid waste.

The remaining vitrified material is inert and can be cast into molds to produce tiles, blocks or plates for the construction industry. EER then purifies the gas and with it operates turbines to generate electricity. EER produces energy - 70% of which goes back to power the reactor with a 30% excess which can be sold. It [the vitrified slag] also makes a good recyclable material for building and paving roads.

In conclusion, considering both the current technology which has been used worldwide to successfully manage spent fuel as well as new technologies which have been demonstrated or proposed, simply burying spent fuel seems both economical and ecologically foolish. Reprocessing and other methods can dramatically reduce the amount of material to be disposed of and also the total radioactivity. Burring spent fuel means one has to deal with the “worst of both worlds,” that is material which is both immediately high in radiation and which poses long-term disposal concerns.

Yes!!! We are the young generation, we are the young Malaysians, it is our future we are talking about, and we want a sustainable, green, beautiful, secure planet that we can show our own children with our very own eyes instead of just through pictures in history books – We want a future. And let us manage the waste!!!

Dont underestimate us in this matter!!! We are climbing the future tremendously towards green world!!! We are the shaper of the next world!!! We are the future!!!

0 comments:

Post a Comment