Uranium and Nuclear Power in Kazakhstan

(updated October 2010)

- Kazakhstan has 15% of the world's uranium resources and an expanding mining sector, expecting 18,000 tU annual production in 2010, planning for 25,000 tonnes in 2011, and 30,000 tonnes per year by 2018.

- In 2009 it became the world's leading uranium producer, with almost 28% of world production.

- A single nuclear power reactor operated from 1972 to 1999, generating electricity and for desalination.

- Kazakhstan has a major plant making nuclear fuel pellets and aims eventually to sell value-added fuel rather than just uranium. It aims to supply 30% of the world fuel fabrication market by 2015.

- The government is committed to increased uranium exports, and is considering future options for nuclear power.

Kazakhstan has been an important source of uranium for more than fifty years. Over 2001-2009 production rose from 2000 to 14,020 tonnes U per year, and further mine development is under way with a view to annual production of 18,000 tU/yr in 2010 and 30,000 tU by 2018. Production in 2009 was 13,900 tU, making Kazakhstan the world's leading uranium producer.

Kazakhstan has no national electricity grid, but a northern grid links to Russia and a southern one links to Kyrgystan and Uzbekistan. Electricity consumption is 48 TWh/yr, from 17 GWe of plant, mostly fossil fuel fired and now privatised.

Kazatomprom is the national atomic company set up in 1997 and owned by the government. It controls all uranium exploration and mining as well as other nuclear-related activities, including imports and exports of nuclear materials. It announced in 2008 that it aims to supply 30% of the world uranium by 2015, and through joint ventures: 12% of uranium conversion market, 6% of enrichment, and 30% of the fuel fabrication market by then.

Recent international collaboration

Kazatomprom has forged major strategic links with Russia, Japan and China, as well as taking a significant share in the international nuclear company Westinghouse. Canadian and French companies are involved with uranium mining and other aspects of the fuel cycle.

In July 2006 Russia and Kazakhstan (Kazatomprom) signed three 50:50 nuclear joint venture agreements totalling US$ 10 billion for new nuclear reactors, uranium production and enrichment. The first JV with Atomstroyexport is JV Atomniye Stantsii for development and marketing of innovative small and medium-sized reactors, starting with OKBM's VBER-300 as baseline for Kazakh units. Russia's Atomstroyexport expected to build the initial one.

The second JV with Tenex, confirmed in 2008, is for extending a small uranium enrichment plant at Angarsk in southern Siberia (this will also be the site of the first international enrichment centre, in which Kazatomprom has a 10% interest). It will eventually be capable of enriching the whole 6000 tonnes of uranium production from Russian mining JVs in Kazakhstan. See Fuel Cycle section below.

The uranium exploration and mining JVs Akbastau and Karatau with Tenex started with Budenovskoye in the Stepnoye area of south Kazakhstan, which commenced production in 2008. These complemented the Zarechnoye JV 250 km to the south which was set up in June 2006. However, in 2009 and 2010 the 50% ARMZ equity in these three was traded for an eventual 51% share of Canadian-based Uranium One.

In April 2007 a number of high-level agreements on energy cooperation were signed with Japan. These included some relating to uranium supply to Japan, and technical assistance to Kazakhstan in relation to fuel cycle developments and nuclear reactor construction. A further agreement on uranium supply and Japanese help in upgrading the Ulba fuel fabrication plant was signed in may 2008. Kazatomprom is keen to move from being a supplier of raw materials to selling its uranium as fabricated fuel assemblies. It said that it aimed to supply 40% of the Japanese market for both natural uranium and fabricated fuel from 2010 - about 4000 tU per year. Negotiations then commenced for a bilateral nuclear cooperation agreement between Kazakhstan and Japan.

In August 2006 The Japan Bank for International Cooperation had signed an agreement with Kazatomprom to support and finance Japanese firms in developing Kazakh uranium resources to supply Japan's power generation. In March 2009 three Japanese companies - Kansai, Sumitomo and Nuclear Fuel Industries - signed an agreement with Kazatomprom on uranium processing for Kansai plants. In March 2010 a joint venture with Sumitomo was set up: Summit Atom Rare Earth Company, and in June, Kazatomprom and Toshiba Сorp. agreed to set up a rare earth metals joint venture. In September 2010, based on an April 2007 agreement, Japco, Toshiba and Marubini signed a technical cooperation agreement with the National Nuclear Centre (NNC) to study the feasibility of building nuclear power capacity (see nuclear power section).

In December 2006 China Guangdong Nuclear Power Group Holdings (CGNPC) signed a strategic cooperation agreement with Kazatomprom, in May 2007 an agreement on uranium supply and fuel fabrication, and in September 2007 agreements on Chinese participation in Kazakh uranium mining joint ventures and on Kazatomprom investment in China's nuclear power industry. This is a major strategic arrangement for both companies, with Kazatomprom to become the main uranium and nuclear fuel supplier to CGNPC (accounting for a large share of the new reactors being built in China). In October 2008 a further agreement was signed covering cooperation in uranium mining, fabrication of nuclear fuel for power reactors, long-term trade of natural uranium, generation of nuclear electricity and construction of nuclear power facilities. A CGNPC subsidiary, Sino-Kazakhstan Uranium Resources Investment Co, is to invest in two Kazakh uranium mines, Irkol and Semizbai, through the Semizbai-U LLP joint venture.

A framework strategic cooperation agreement was signed with China National Nuclear Corporation (CNNC) in September 2007 and this was followed in October 2008 with another on "long-term nuclear cooperation projects" under which CNNC is to invest in a uranium mine. Late in 2007 Kazatomprom signed an agreement with both GCNPC and CNNC for them to take a 49% stake in two uranium mine joint ventures and supply 2000 tU per year from them. Kazatomprom estimates that 20% of its uranium output goes to China, with the possibility of this increasing with demand as production heads for 25,000 tU/yr.

Early in 2009 Kazatomprom signed an agreement with CGNPC for establishment of a specialized company for the construction of nuclear power plants in China, since Kazakh plans to work with Russia's Atomstroyexport developing and marketing innovative small and medium-sized reactors had been put on hold. As of mid 2009 a feasibility study on this joint CGNPC project was underway.

In January 2009 Kazatomprom signed an agreement with India's Nuclear Power Corporation (NPCIL) to supply 2100 tonnes of uranium to India and undertake a feasibility study on building Indian PHWR reactors in Kazakhstan. NPCIL said that it represented "a mutual commitment to begin thorough discussions on long-term strategic relationship." Under this agreement, 300 tonnes of natural uranium will be supplied by Kazatomprom in the 2010-11 year.

In April 2010 Kazakhstan signed a nuclear cooperation agreement with South Korea, paving the way for export of Korean SMART 100 MWe nuclear reactors and for joint projects to mine and export Kazakh uranium.

In addition Kazakhstan has signed intergovernmental agreements on nuclear energy cooperation with the USA and Euratom.

At the corporate level, in 2007 Kazatomprom purchased a 10% share in Westinghouse. Toshiba had bought the company from BNFL for $5.4 billion early in 2006, and the Shaw Group then took 20% and IHI Corp. 3%. Toshiba originally envisaged holding only 51%, and this deal reduced its holding to 67%. The Kazatomprom link strengthened the company's upstream links for fuel supplies, and should enhance its marketing of nuclear reactors (the vendor usually supplies the first core for a new reactor, and ongoing fuel services may be offered in addition). It also brought Kazatomprom more fully into the industry mainstream, with fuel fabrication in particular.

This led to a decision to set up with Toshiba a nuclear energy institute in the northeastern town of Kurchatov, near Semipalatinsk, which is already a centre of R&D activity. This was announced by Kazatomprom and the Kazakh prime minister in September 2008 and will focus on skills development in all aspects of the nuclear fuel cycle as well as reactor technology. Other Japanese companies such as Toyota and Marubeni are expected to support the institute, especially in its rare earth metals department which aims to utilise present waste materials as the basis of a billion-dollar high-tech export industry. Three research reactors are operated by the Institute of Atomic Energy at Kurchatov.

In May 2007 Canada's Cameco Corporation signed an agreement with Kazatomprom to investigate setting up a uraniumconversion plant, using its technology, and also increasing uranium production at its 60% owned Inkai mine. In June 2008 Cameco and Kazatomprom announced the formation of a new company - Ulba Conversion LLP - to build a 12,000 t/yr uranium hexafluoride conversion plant at the Ulba Metallurgical Plant in Ust-Kamenogorsk. Cameco will provide the technology and hold 49% of the project. A feasibility study is due to be completed mid 2009.

In June 2008 Areva signed a strategic agreement (MOU) with Kazatomprom to expand the existing Katco joint venture from mining 1500 tU/yr to 4000 tU/yr (with Areva handling all sales), to draw on Areva's engineering expertise in a second JV (49% Areva) to install 1200 tonnes per year fuel fabrication capacity at the Ulba Metallurgical Plant, and in a third JV (51% Areva) to market fabricated fuel. In October 2009 the two parties signed another agreement to establish the IFASTAR joint venture to fabricate nuclear fuel at the Ulba plant and market it as integrated fuel supply for Asian customers (ie selling the enriched and fabricated fuel, not simply Kazakh uranium or Areva front-end services). IFASTAR would first undertake a feasibility study on building a 400 t/yr fuel fabrication line at Ulba. IFASTAR is to be based in Paris, with 51% Areva equity (though any resulting plant will be 51% Kazatomprom).

At a corporate and project level, the following table summarises international equity links:

| Company, project or mine | Foreign investor and share | Value of share or project if known |

| Inkai JV (Inkai mines) | Cameco 60% | |

| Betpak Dala JV (South Inkai, Akdala mines) | Uranium One 70% | $350 million for 70% in 2005 |

| Appak JV (W.Mynkuduk) | Sumitomo 25%, Kansai 10% | $100 million total in 2006 |

| JSC Karatau (Budenovskoye 2 deposit) | Uranium One 50% (bought from ARMZ in 2009) | 117 million Uranium One shares (giving 19.9% ownership) + $90 million |

| JSC Akbastau (Budenovskoye 1, 3, 4 deposits) | Uranium One 50% (bought from ARMZ in 2010) | |

| Zhalpak | CNNC 49% | |

| Katco JV (Moinkium, Tortkuduk mines) | Areva 51% | $110 million in 2004 |

| Kyzlkum JV (Kharasan 1 mine) | Uranium One 30%, Japanese 40% (Marubeni, Tepco, Toshiba, Chubu, Tohoku, Kyushu) | $75 million in 2005 for 30%, $430 million total in 2007 (both mines) |

| Baiken U JV (Kharasan 2 mine) | Japanese 40% (Marubeni, Tepco, Toshiba, Chubu, Tohoku, Kyushu) | $430 million total in 2007 (both mines) |

| Semizbai-U JV (Irkol, Semizbai mines) | CGNPC 49% | |

| Zarechnoye JV (Zarechnoye & S.Zarechnoye mines) | Uranium One 49.67% (bought from ARMZ in 2010) | ARMZ paid $60 million total |

In 2009 investigations were launched into how, and at what prices, certain Kazakh entities came to hold title to particular mineral deposits before those rights were sold to international investors, particularly some of those above. In June 2009 Kazatomprom reassured its foreign joint venture and equity partners in uranium mining, from Japan, Russia, Canada, France and China that existing arrangements with foreign partners would not be changed, despite criminal charges being laid against former Kazakh executives.

The transfer to Uranium One of ARMZ's half shares in Akbastau and Zarechnoye (valued at US$ 907.5 million) in 2010 involves payment by ARMZ of US$ 610 million in cash (at least US$ 479 million of which will be paid directly to shareholders - other than ARMZ - as a change of control premium) and ARMZ increasing its shareholding in Uranium One from 23% to at least 51% through a share issue.

Uranium mining

Uranium exploration started in 1948 and economic mineralisation was found is several parts of the country and this supported various mines exploiting hard rock deposits. Some 50 uranium deposits are known, in six uranium provinces. Reasonably Assured Resources plus Inferred Resources to US$ 130/kgU were 816,000 tU at 2005.

In 1970 tests on in situ leach (ISL) mining commenced and were successful, which led to further exploration being focused on two sedimentary basins with ISL potential.

Up to 2000 twice as much uranium had been mined in hard rock deposits than sedimentary ISL, but almost all production is now from ISL. Uranium production dropped to one quarter of its previous level 1991 to 1997.

Kazakh Uranium Production and Revenue

| year | 1997 | 1998 | 1999 | 2000 | 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 |

| tonnes U | 795 | 1073 | 1367 | 1752 | 2022 | 2709 | 2946 | 3712 | 4362 | 5281 | 6637 | 8521 | 14020 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| revenue | 6405 | 8660 | 15876 | 18361 | 19954 | 23822 | 28330 | 36849 | 50567 | 89422 |

Source: Kazatomprom, currency KZT million

Projections are for 2010: 15,450 tU and 2015: 24,000 tU.

The last surviving underground mines at Grachev and Vostok in the Northern province had been operating since 1958 and are now rather depleted. KazSabton operated them, having taken over from Tselinny Mining & Chemical Co in 1999. It treated the ore at the Stepnogorsk mill, yielding some 250 tU per year. Production from the Stepnogorsk Mining & Chemical Complex plant is now listed as some 500 tU/yr going forward to 2010. The Semizbai ISL project is also in the Northern province, Akmola region, and Semizbai-U was formed in 2006 to mine it.

In the Balkash province some mining of volcanogenic deposits occurred during the Soviet era. In the Ili province east of this there is some uranium in coal deposits.

In the Caspian province the Prikaspisky Combine operated a major mining and processing complex on the Mangyshalk Peninsula in the 1960s and this led to the founding of Aktau. It was privatised as Kaskor in 1992 and operations ceased in 1994.

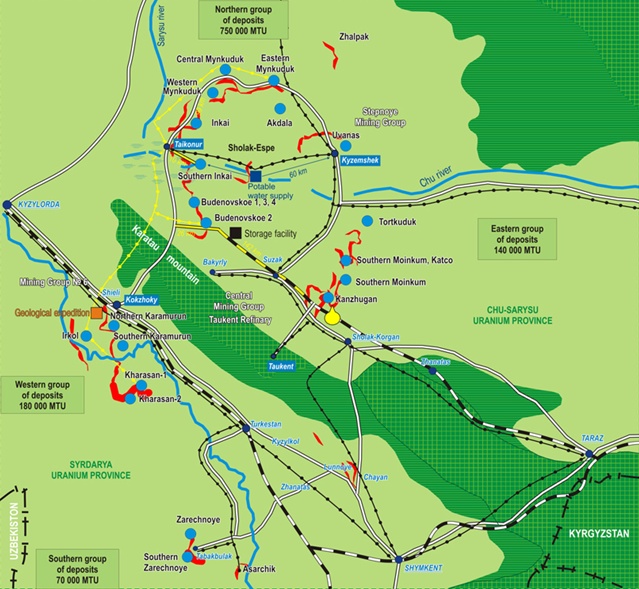

map from KazAtomProm 2007. Scale: Kyzlorda to Shieli/ Kokzhoky is about 100km.

All except one of the operating and planned ISL mine groups are in the central south of the country and controlled by the state corporation Kazatomprom. Mines in the Stepnoye area have been operating since 1978, some in the Tsentralnoye area since 1982 - both in the Chu-Sarysu basin/ province, which has more than half the country's known resources. Mines in the Western (No.6) area of the Syrdarya basin/ province have operated since 1985. All have substantial resources.

The ISL mines and projects in the two central southern provinces are in four groups, as set out below. Production costs from these are understood to be low. Uranium One in September 2007 was quoting "cash cost" figures of $8.00 to $10.50/lb for three mines it is involved with. A further feature of Kazakh uranium mining is that Kazatomprom plans to establish new mines in three years, compared with twice this time or more in the West, due to regulatory hurdles.

Inkai is the largest ISL mine, and Cameco's description of its operation is: Uranium occurs in sandstone aquifers as coatings on the sand grains at a depth of up to 300 metres. Uranium is largely insoluble in the native groundwater which is not potable due to naturally high concentrations of radionuclides and dissolved solids. Using a grid of injection and production wells, a mining solution containing an oxidant (sulfuric acid) is circulated through the orebody to dissolve the uranium. The uranium-bearing solution (generally containing less than 0.1% uranium) is then pumped to a surface processing facility where the uranium is removed using ion exchange resin. The water is re-oxidized and re-injected into the orebody. The uranium is stripped from the resin, precipitated with hydrogen peroxide and then dried to form the final product, U3O8. This process is repeated to remove as much uranium as is economically feasible. When mining at the site is complete, the groundwater will be restored to its original quality.

This is a closed loop recirculation system since the water from the production well is reintroduced in the injection wells. Slightly less water is injected than is pumped to the surface to ensure that fluids are confined to the ore zones intended for extraction. Monitor wells are installed above, below and around the target zones to check that mining fluids do not move outside a permitted mining area.

Acid production

ISL uranium production in Kazakhstan requires large quantities of sulfuric acid*, due to relatively high levels of carbonate in the orebodies. A fire at a sulfuric acid production plant in 2007 led to shortages, and due to the delayed start-up of a new plant, rationing continued until mid 2008. Extra supplies were sought from Uzbekistan and Russia, but uranium production well into 2009 was affected. Uranium One revised its 2008 production downwards by 1080 tU, which it said was "primarily due to the acid shortage" for its South Inkai and Kharasan projects (70% and 30% owned respectively) which were just starting up. In August 2009 Cameco reported that production at Inkai would remain constrained through 2009 due to acid shortage.

* 70-80 kg acid/kgU (comprising 15-20% of the operating expense), compared with Beverley in Australia at around 3 kg/kgU.

A new 1.2 million t/yr Canadian acid plant feeding from the Kazakhmys copper smelter in Balkhash started production at the end of June 2008, financed by an EBRD loan to abate sulfur dioxide emissions from copper smelting. A 360,000 t/yr acid plant at the Stepnogorsk Mining and Chemical Combine started in 2006. A second Stepnogorsk plant of 180,000 t/yr capacity, from Italy, is expected to be operational in 2010.

Another new acid plant, of 500,000 t/yr capacity, is under construction at Zhanakorgan, next to the Kharasan mines in the Western (#6) mining group or Kyzlorda region, to serve those mines from 2011 and reach design capacity in 2012. It will burn 170,000 t/yr of solid sulfur derived from oil and gas production by Tengizhevroil in western Kazakhstan. Uranium One is participating in a joint venture with Kazatomprom and Japanese interests to build this US$ 216 million project and will have a 19% interest with Japanese interests 32%.* The new plant will supply all the Western region mines: Kharasan, Irkol and Karamurun.

* Construction of the plant is being carried out by SKZ-U LLP joint venture, in which Baiken-U LLP (40%) and Kyzylkum LLP (60%) are the stakeholders.

In 2009 Kazatomprom with other mining companies and two acid producers, KazZinc JSC and Kazakhmys, set up a coordinating council to regulate acid supplies and infrastructure.

Kazakh ISL uranium mines

| Region | Mine | Resources tU | Operator | Annual production target tU/yr | Start production, full prod'n |

| Chu-Sarysu Province | |||||

| Northern/Stepnoye group | Uvanas | 8100 | Stepnoye-RU LLP (K'prom) | 400 | 2006 |

| East Mynkuduk | 22,000 | 1300 | 2006, 2007 | ||

| Inkai 1, 2, 3 | reserves 52,000 | Inkai JV: Cameco 60%, K'prom 40% | 2000, 4000 later | 2008, 2010 | |

| South Inkai | Reserves 13,000, in 15,260 indicated, 17,100 inferred | BetpakDala JV: Uranium One 70%, K'prom 30% | 2000 | 2007, 2011 | |

| Akdala | Reserves 5240, in 25,500 | 1000 | 2006, 2007 | ||

| Central Mynkuduk | 52,000 | JSC Ken Dala.kz Stepnogorsk (K'prom) | 2000 | 2007, 2010 | |

| West Mynkuduk | 26,000 | Appak JV: K'prom 65%, Sumitomo 25%, Kansai 10% | 1000 | 2008, 2010 | |

| Akbastau (Budenovskoye 1, 3, 4) | 20,000 | JV Akbastau: K'prom 50%, ARMZ 50% (to Uranium One in 2010) | 1000 (1) 2000 (3,4) | 2010, 2015 2010 | |

| Karatau (Budenovskoye 2) | Reserves 11,290 | JV Karatau: K'prom 50%, Uranium One 50% | 2000 | 2008, 2011 | |

| Zhalpak | 15,000 | JV with China (CNNC 49%) | 1000 | 2012? | |

| Central/East (Tsentralnoye) group | Moinkum (southern Moinkum, Katco) | 44,000 | Katco JV, Areva 51%, K'prom 49% | 1000 | 2006, 2007 |

| Tortkuduk (Moinkum North) | 20,000 | 2000 | 2007, 2008 | ||

| South Moinkum (east Moinkum) | 35,000 | Taukent Mining & Chemical Plant LLP (K'prom) | 1000 | 2006 | |

| Kanzhugan / Kaynarski | 22,000 | 300 | 2007 | ||

| Syrdarya Province | |||||

| Western (no.6) group | Kharasan 1(north) | 41,000 | Kyzylkum JV, Japanese 40%, Uranium One 30%, K'prom 30% | 3000 | 2010, 2014 |

Kharasan-2 | Baiken-U JV, Japanese 40%, K'prom 60% | 2000 | 2010, 2014 | ||

| Irkol | 30,000 | Semizbai-U JV (K'prom 51%, CGNPC 49%) | 750 | 8/2008, 2010 | |

| N. Karamurun | 16,000 | Ru-6 LLP (K'prom) | 1000 | 2007, 2010 | |

| S. Karamurun | 18,000 | Ru-6 LLP (K'prom) | 250 | 2009 | |

Southern group | Zarechnoye | 40,000 | Zarechnoye JV: K'prom 49%, ARMZ 49% (to Uranium One in 2010) | 1000 | 2007, 2011 |

| Southern Zarechnoye | 620 | 2014 | |||

| Northern Province | |||||

| Akmola region | Semizbai | Semizbai-U JV (K'prom 51%, CGNPC 49%) | 500 (680 later) | 2009, 2018 | |

The Stepnoye or Northern mining group in the Chu-Sarysu basin consists of Uvanas, East Mynkuduk, Akdala and Inkai mines, with Central and West Mynkuduk, South Inkai, Budenovskoye and Zhalpak planned. All are amenable to in-situ leaching (ISL).

Uvanas is a small deposit which commenced operation in 2006.

Inkai was discovered in 1976, and the Inkai Joint Venture (JVI) is developing the Inkai mine in this part of the Chu-Sarysu basin. JVI was set up in 1996 (then including Uranerz), and now Cameco holds 60% with Kazatomprom (40%). Following a 2-year feasibility study completed in 2004, and regulatory approval in 2005, JVI invested US$ 38 million in an ISL operation which started commercial production in 2008 and is ramping up to 2000 tU/yr, though as of mid 2010 it was only licensed for half this - 2009 production was 720 tU and projected 2010 production is 1500 tU. Eventual production from blocks 1 & 2 is envisaged as 4000 tU/yr, and application for 3000 tU/yr is in train.

Total cost of the JVI development was projected as US$ 200 million, though remaining capital costs at the start of 2010 were quoted at $359 million. The main processing plant on block 1 has an ion exchange capacity of 1000 tU/yr and a product recovery capacity of 2000 tU/yr. A satellite 1000 tU/yr IX plant is on block 2 and two further such plants are proposed. JVI holds an exploration licence for block 3. Cameco has reported 52,000 t U3O8 proven and probable reserves plus 8440 t indicated and 98,300 t inferred resources for blocks 1 & 2 (Dec 2009, NI 43-101 compliant). Operating cost over the life of the mine are estimated to be $17.55/lb concentrate (March 2010).

In September 2005 UrAsia Energy Ltd of Canada agreed to pay US$ 350 million for 70% of the Betpak Dala joint venture which owns the South Inkai project and the Akdala mine. The company (UrAsia) is now Uranium One Inc.

South Inkai mine started trial production in 2007 and is ramping up to 2000 tU/yr in 2011. In 2008 pre-commercial production was 436 tU and production in 2009 was 830 tU. Commercial production officially began in January 2009, but aspects were still under construction. Cash operating cost in 2009 was $21/lb of concentrate.

The NI 43-101 resource estimate for South Inkai is 15,260 tU indicated resources and 17,100 tU inferred resources as at end of 2008. Average grade is 0.053% and 0.047% respectively.

Akdala started up in 2006 and produced 1031 tU in 2008 and 1046 tU in 2009, at cash operating cost of $14/lb of concentrate. Well installation continued through 2009. Akdala has proven & probable reserves of 9500 tU, and 16,000 tU indicated & inferred resources.

Central Mynkuduk mine started up in 2007 and was expected to reach capacity of 2000 tU/yr by 2010. It is operated by the Ken Dala.kz joint stock company, part of Kazatomprom.

West Mynkuduk: Early in 2006 KazAtomProm signed a US$ 100 million joint venture agreement with Sumitomo Corp (25%) and Kansai Electric Power Co (10%) to develop the deposit. First production from the Appak JV was in June 2008 with design capacity of 1000 t/yr expected in 2010. Sumitomo will supply uranium from the mine to Japanese power utilities.

The East Mynkuduk mine was launched in May 2006 by Kazatomprom to achieve its planned 1000 t/yr production in 2007.

The Karatau mine at the south end of the Budenovskoye deposit started production in 2008 (655 tU), and is ramping up to a capacity of 2000 tU/yr by 2011. The production rate in January-February 2010 was 1460 tU/yr, and 2009 operating cost was $12/lb of concentrate. A uranium refinery is reported to be under construction there. The Akbastau mine (Budenovskoye 1, 3, 4) just north of this started production at the end of 2009 and produced 385 tU that year, with treatment being at Karatau. It is ramping up to 3000 tU/yr by 2015. Akbastau has indicated resources of 11,400 tU and inferred resources of 24,500 tU at mid 2009.

In July 2006 both Budenovskoye operations became 50:50 JVs with Russia, complementing Zarechnoye, but in 2009 ARMZ's share in Karatau was sold to Uranium One. In 2010 ARMZ's share in Akbastau was also transferred to Uranium One.

Zhalpak: A Chinese (CNNC)-Kazatomprom joint venture is being set up to develop the deposit. This could produce up to 1000 tU/yr from resources of 15,000 tU, starting about 2012.

The Central or Eastern mining group (Tsentralnoye) in the Chu-Sarysu basin comprises Moinkum, Southern Moinkum, Kanzhugan, Tortkuduk mines, plus the new refinery.

Moinkum (Muyunkum): Following three years' pilot plant operation, Areva and the state utility Kazatomprom agreed in April 2004 to set up a 1500 tU/yr in situ leach (ISL) uranium venture at Moinkum in this part of the Chu-Sarysu basin. Areva holds 51% and funded the US$ 90 million Katco joint venture, having spent some US$ 20 million already since 1996. Resources are 52,000 tU3O8. Operation began in June 2006, with capacity eaching almost its full 500 tU in 2007.

Tortkuduk (Moinkum North) is also part of the Katco JV and was expected to reach full production of 1000 tU/yr by the end of 2008.

A June 2008 agreement expanded the Katco joint venture from mining 1500 tU/yr to 4000 tU/yr and sets up Areva to handle all sales from it through to 2039. In 2008 Areva reported total Muyunkum phase 1 production as 1356 tU.

The Kanzhugan deposit supports the Kaynar mine which was due to start up in 2008, with nominal capacity of 300 tU/yr.

The Western mining group (#6) is in the Syrdarya basin and comprises the North and South Karamurun mines operated by Mining Company #6, with Irkol and (North) Kharasan 1 & 2.

Kharasan: In 2005 UrAsia Energy Ltd (now Uranium One Inc) of Canada paid US$ 75 million for a 30% share of the Kyzylkum joint venture which owns the (North) Kharasan project. Kharasan has indicated & inferred resources of 41,000 tU. (In March 2006, NI 43-101 convention: 5300 tU indicated and 29,000 tU inferred, with potential for another 40,000 tU.)

Kharasan 2 is to the south of this and was owned by Kazatomprom but is now controlled by the Baiken-U joint venture, including Japanese equity. Pilot production commenced in 2009.

In April 2007 several Japanese companies bought 40% of the Kharasan project and will directly take 2000 tU/yr when it is in full production at 5000 tU/yr about 2014. Of that share, Marubeni had 55%, Tepco 30%, Chubu 10% and Tohoku 5%. When Toshiba agreed to sell part of Westinghouse to Kazatomprom, it agreed to buy 9% of Kharasan from Marubeni (ie 22.5% of the Japanese stake). Then Kyushu Electric Power Co bought 2.5% of the Japanese stake, leaving Marubeni with 30%. The Japanese consortium share in both JVs is now: Marubeni 12%, Tepco 12%, Toshiba 9%, Chubu 4%, Tohoku 2% and Kyushu 1%. Project funding is $70 million from the Japan Bank for International Cooperation and $30 million from Citibank. Project funding is expected from the Japan Bank for International Cooperation.

A 2000 tU per year processing facility is matched with a 1000 tU/yr satellite plant. Pilot production commenced in April 2009 with Kharasan 1 to reach 3000 tU/yr by 2014, and Kharasan-2 to reach 2000 tU/yr in 2014. Pre-commercial mining commenced in 2008 and production in 2009 was expected to reach 180 tU, but may be less. First significant production for both was early 2010. Production from the $430 million project will primarily supply Japanese utilities. In August 2009 Kazatomprom announced that a wrong technological decision in 2006 regarding development of the deposits had "led to a failure of the 2008-09 production program" and consequent lack of funds, but this was being rectified. Uranium One said that bore holes had been drilled incorrectly and that organic matter was increasing acid consumption.

Irkol started up in 2008, and in 2009 was expected to produce about 500 tU, ramping up for 750 tU/yr by 2010. In October 2008 it was announced that China's CGNPC would take a 49% share of it through the Semizbai-U JV (see introductory section and below). The mine was formally opened in April 2009 with some fanfare, as the first mine to be put into commercial operation within the framework of the Kazakhstan-CGNPC nuclear power agreement. All the production will be claimed by or sold to CGNPC.

Karamurun: North Karamurun was expected to start up in 2007, South Karamurun in 2009.

The Southern mining group in the same Syrdarya basin has the Zarechnoye mine.

Zarechnoye, discovered in 1977, started production at the end of 2006. Reserves are quoted at 19,000 tU. The US$ 60 million Zarechnoye joint venture involved Kazatomprom (49.67%), ARMZ (49.67% - to provide finance) and Kyrgyzstan's Kara Baltinski Mining Combine (0.66%), which is processing the ore there. The mine produced 166 tU in 2008 and 500 tU in 2009. It is expected to reach full production at 960 tU/yr by 2012. In mid 2010 ARMZ agreed to transfer its share to Uranium One.

South Zarechnoye was discovered in 1989 and is being developed by the same joint venture to commence production in 2014, eventually at 620 tU/yr.

In June 2006 Tenex signed a US$ 1 billion uranium supply contract with Zarechnoye JV for up to 6000 tU per year from 2007 to 2022. Initially this will come from Zarechnoye mine, but Budenovskoye will also contribute.

Outside of these two basins, in the Northern Kazakhstan province, the Semyibai ISL mine is due to be commissioned at the end of 2009. It will have a capacity of 500 tU/yr from a uranium-rare earth deposit, and in October 2008 it was announced that China's CGNPC would take a 49% share of it. It will be managed by Semizbai-U LLP, a joint venture.

Earlier, Itochu Corp of Japan has signed a uranium purchase agreement with KazAtomProm for some 3000 tonnes of uranium over 10 years to be marketed in Japan and the USA. KazAtomProm intends to use a US$60 million loan from Japan¹s Mizuho Corporate Bank to raise uranium production at the Central Mynkuduk deposit to 1000 tU/yr, of which Itochu Corp will receive 300t.

Kazkh Uranium Resources

| province | resources: tonnes U | proportion of Kazakh |

|---|---|---|

| Chu-Sarysu | 60.5% | |

| Northern (Stepnoye) group | 750,000 | |

| Eastern (Tsentralnoye) group | 140,000 | |

| Syrdarya | 12.4% | |

| Western (#6) group | 180,000 | |

| Southern (Zarechnoye) group | 70,000 | |

| Northern | 256,000 | 16.5% |

| Ili | 96,000 | 6% |

| Caspian | 24,000 | 1.8% |

| Balkash | 6,000 | 0.4% |

The Chu-Sarysu and Syrdarya deposits are all suitable for ISL recovery, the Northern deposits are mostly in hard rock, Ili mineralisation is in coal deposits, Caspian has phosphate deposits, and Balkhash has some hard rock mineralisation but the major deposits were exhausted in the Soviet era.

All uranium is exported, and with the 2006 joint venture agreements, Russia will be the main customer, but with China and Japan both assuming greater importance.

Fuel cycle

In 2006 a joint venture was set up with Russia's Tenex is for uranium enrichment at Angarsk in southern Siberia where Russia has its main conversion plant and a small enrichment plant. It will eventually be capable of enriching the whole 6000 tonnes of uranium production from Russian mining JVs in Kazakhstan.

The internationally-significant Ulba Metallurgical Plant at Ust Kamenogorsk in the east of the country was commissioned in 1949. It has a variety of functions relevant to uranium, the most basic of which since 1997 is to refine most Kazakh mine output of U3O8. (It also produces beryllium, niobium and tanatalum.)

In June 2008 the formation of a new company - Ulba Conversion LLP - was announced, to build a 12,000 t/yr uranium hexafluoride conversion plant here, with Cameco providing the technology and holding 49% of the project. Ulba has produced HF since 1952, and the new conversion subsidiary will fit in with Russian JV enrichment arrangements. Construction is expected to start in 2009.

Kazatomprom has a JV with Tenex for adding to the uranium enrichment plant at Angarsk in southern Siberia where Russia has its main conversion plant and a small enrichment plant now being expanded to 4.2 million SWU/yr. Kazatomprom and Tenex agreed to finance a 5 million SWU/yr increment to this. Each party would contribute about US$ 1.6 billion and Kazatomprom would hold 50% equity. This is distinct from the International Uranium Enrichment Centre (IUEC). However, in mid 2010 it was reported that instead of building this new capacity, a share of the Urals Electrochemical Combine which has a 10 million SWU/yr plant at NovoUralsk would be transferred to Kazatomprom.

In September 2007 the joint stock company Angarsk International Uranium Enrichment Centre (IUEC) was registered with 10% Kazatomprom ownership and the balance Techsnabexport (Tenex). This share is being sold down to other partners - Ukraine confirmed 10% share in 2008, and Tenex is to hold only 51% eventually.

Since 1973 Ulba has produced nuclear fuel pellets from Russian-enriched uranium which are used in Russian and Ukrainian VVER and RBMK reactors. Some of this product incorporates gadolinium and erbium burnable poisons. Other exports are to the USA and Asia. Ulba briefly produced fuel for submarines (from 1968) and satellite reactors. Since 1985 it has been able to handle reprocessed uranium, and it has been making fuel pellets incorporating this for western reactors, supplied through TVEL.

Ulba Metallurgical Plant is majority owned by Kazatomprom and 34% by Russia's TVEL and has major new investment under way. It has secured both ISO 9001 and ISO 14001 accreditation. In 2007 a technological assistance agreement was signed with Japan apparently in line with government announcements that it would move towards selling its uranium as fabricated fuel or at least fuel pellets rather than just raw material. (One agreement is on fabrication of nuclear fuel components, between Kazatomprom, Kansai Electric and Sumitomo Corp.) In 2010, UO2 powder for Japan was certified by Japan's Nuclear Fuel Industries.

Kazatomprom has said that it aims to supply up to one third of the world fuel fabrication market by 2030, with China to be an early major customer. In June 2008 Areva signed a memorandum of understanding to provide engineering expertise to build a 1200 t/yr fuel fabrication plant as part of the Ulba complex, utilising fuel pellets from it. It will include a dedicated 400 t/yr line (51% owned by Kazatomprom, 49% Areva) specifically for fuel for French-designed reactors, including those in China. CGNP has confirmed that Kazatomprom is to become a major nuclear fuel supplier. The other 800 t/yr line will be wholly owned by Kazatomprom. Kazatomprom is also negotiating technology transfer agreements to enable it to supply fabricated fuel for Westinghouse reactors, now that it owns a 10% stake in Westinghouse.

Nuclear power

The BN-350 fast reactor at Aktau (formerly Shevchenko), on the shore of the Caspian Sea, successfully produced up to 135 MWe of electricity and 80,000 m3/day of potable water over some 27 years until it was closed down in mid 1999. About 60% of its power was used for heat and desalination. It was operated by the Mangyshlak Power Generation Co. (MAEK).

The Russian plant, built under Minatom supervision, was designed as 1000 MWt but never operated at more than 750 MWt and was most recently quoted at 520 MWt, but it established the feasibility and reliability of such cogeneration plants. (In fact, oil/gas boilers were used in conjunction with it, and total desalination capacity through ten multi-effect distillation (MED) units was 120,000 m3/day.)

Kazakh plans for nuclear power include large light-water reactors for the southern region, 300 MWe class units for the western part and smaller cogeneration units in regional cities. There are proposals for a new nuclear power plant near Lake Balkhash in the south of the country near Almaty.

The July 2006 Atomniye Stantsii JV with Atomstroyexport envisages development and export marketing of innovative small and medium-sized reactors, starting with OKBM Afrikantov's VBER-300 PWR as baseline for Kazakh units. Russia's Atomstroyexport expects to build the initial pair and Kazatomprom announced that it planned to start construction in 2011 for commissioning of the first unit in 2016 and the second in 2017 at Aktau in the Mangistau region, on the Caspian Sea. The plant would then be marketed internationally.

However, the project then stalled over funding, and alleged Russian reluctance to transfer intellectual property rights on the VBER reactor. It was reactivated in 2009, with Aktau as the site, and this was confirmed in a feasibility study completed in 2010 which showed that for an electricity price of 8 tenge (US$0.05) per kWh, the plant would be paid off in 12 years. The project has passed environmental review. Kazakh officials had been seeking Russian guarantees on costs and technical issues for the first plant, and OKBM was looking for new partners to develop the design. The Atomic Energy Committee said it would call tenders for the first plant, to be built by 2020, but that the JV with Russia was the leading contender. An intergovernmental agreement in November 2010 has been reported as likely.

In April 2007 two agreements with Japan related to assistance in building nuclear power plants, one between Japan Atomic Power Co and three Kazakh entities, the other between Toshiba Corp and Kazatomprom. In June 2008 a further agreement on high-temperature gas-cooled reactor research was initialled by the Japan Atomic Energy Agency (JAEA) and the Kazakhstan Atomic Energy Committee, focused on small cogeneration plants.

Further to these, in September 2009 the country's National Nuclear Centre (NNC) announced that an agreement had be signed with JAEA to build a 600 MWe nuclear power reactor, starting in 2010. Due to limited options being offered by reactor vendors for this size of unit, the Japanese offer to re-design and downrate an existing 700 MWe reactor was accepted. NNC said that advantages of this reactor included higher fuel burnup, high thermal efficiency and some capability of hydrogen production in commercially viable amounts.

In September 2010, based on the April 2007 agreement, Japan Atomic Power Co, Toshiba and Marubeni signed a technical cooperation agreement with the National Nuclear Centre (NNC) to study the feasibility of building nuclear power capacity. Toshiba said that the Japan Atomic Power Co would provide, through the overall management of the project, proposals such as construction cost estimates, advice on law and regulation, scheduling, and establishment of an operating body. Toshiba would focus on the plant concept, and Marubeni Utility Services would assess economic feasibility including financial evaluation and financing.

The Ministry of Energy and Mineral Resources of Kazakhstan and the NNC were considering four potential sites for the 600 MWe nuclear power plant: on the shore of Lake Balkhash, in Aktau (west of country), Kustanai (north) and Kurchatov. Early in 2010 Eastern Kazakhstan became the likely location, for a boiling water reactor to be built by JAPC, which operates two in Japan. This project is on the state program of nuclear industry development in Kazakhstan for 2010-20, which is being developed by the Ministry of Energy and Mineral Resources, NNC and Kazatomprom, and submitted for approval to the government.

The National Nuclear Centre (NNC) has proposed constructing 20 or more small reactors each of 50-100 MWe to supply dispersed towns, the first being at Kurchatov.

Radioactive Waste Management

The country has a major legacy of radioactive wastes from uranium mining, nuclear reactors, nuclear weapons testing, industrial activities, coal mining and oilfields.

A specific law covers radioactive waste management, and a new radioactive waste storage and disposal system is under consideration.

A US-Kazakh agreement covers management of spent high-enriched reactor fuel.

Decommissioning of the BN-350 fast reactor at Aktau is under way, with extensive international support. Spent fuel is stored at site, as is 1000 tonnes of radioactive sodium.

Semilpalatinsk hosted 470 nuclear weapons tests in the Soviet era and there remains a significant legacy of environmental damage there.

Research & Development

The National Nuclear Centre (NNC) was set up in 1992. The NNC is responsible for research on the peaceful use of nuclear energy and radiation safety and is also responsible for evaluating the consequences of nuclear tests at the now-closed Semipalatinsk Test Site. All nuclear research reactors in Kazakhstan are under the jurisdiction of the NNC.

At Kurchatov (aka Semipalatinsk-21) on the former Semipalatinsk nuclear test site three research reactors owned by the NNC are operated by the Institute of Atomic Energy. A fourth is at Alatau, 15 km from Almaty. The three larger ones are tank-type units of 6, 10 and 60 MW, the newest is a 400 kW high-temperature gas reactor. All were supplied by Russia and use high-enriched fuel.

Also at Kuchatov is the Kazakhstan Material Study Tokamak (KMT), supported by Russia's Kurchatov Institute, which produced its first plasma in 2010. Full commissioning is due in 2011. KMT supports the ITER project with materials testing.

Organisation, Regulation and safety

The government corporation Kazatomprom was set up in 1996-7 to manage the government's stake in uranium mining and nuclear fuel production, as well as import and export of nuclear material. It also regulates uranium mining. KATEP, set up in 1993, formerly was responsible for all this but in 1997 became simply focused on nuclear power plants.

The National Nuclear Centre (NNC) was set up in 1992 to utilise the former Soviet military facilities for civilian research.

The Nuclear Technology Safety Centre was set up in 1997 with US support to manage the shut-down of the BN-350 reactor at Aktau, and foster safety of nuclear power.

The regulatory body responsible for licensing and safety as well as safeguards compliance is the Kazakhstan Committee on Atomic Energy (CAE), formerly the Atomic Energy Agency.

All uranium and nuclear operations - MAEK, Kazatomprom, KATEP, CAE and NNC, come under the Ministry of Energy & Mineral Resources. It operates under the 1997 Atomic Energy Law.

Weapons site clean-up

From 1949 to 1990, when the country was part of the Soviet Union, some 467 nuclear tests were conducted at the 19,000 sq km Semipalatinsk test site, 800 km north of Almaty. They included explosions that were conducted on the surface and in the atmosphere. Five of the surface tests were not successful and resulted in the dispersion of plutonium into the environment. Starting in 1961, more than 300 test explosions were conducted underground, 13 of which resulted in release of radioactive gases to the atmosphere. Operations at Semipalatinsk were formally terminated in 1991.

In 1993, the government informed the IAEA of their concern about the radiological situation in Semipalatinsk and also western areas, and asked for the IAEA's help to characterize and evaluate the radiological situation at the Semipalatinsk test site. Three IAEA missions ensued over 1993-98, and identified a few areas with elevated residual radioactivity. As there are no restrictions on resettlement of the area, monitoring of residents and visitors was undertaken, showing exposure of up to 10 mSv/yr. However, if the "hot spots" were permanently settled, exposures of up to 140 mSv/yr could result. The IAEA concluded that due to budgetary and other constraints, the most appropriate remedial action initially would be to restrict access by people and cattle to those areas.

Non-proliferation

Kazakhstan is a party to the Nuclear Non-Proliferation Treaty (NPT) as a non-nuclear weapons state. Some 1300 nuclear warheads were destroyed after independence. Its safeguards agreement under the NPT came into force in 1994 and all facilities are under safeguards. In February 2004 it signed the Additional Protocol in relation to its safeguards agreements with the IAEA, and this came into force in 2007.

References:

IAEA 2002, Country Nuclear Power Profiles

IAEA 2002, Uranium 2001: Resources, Production and Demand (Red Book)

Perera, Judith 2003, Nuclear Power in the Former Soviet Union, vols 1 & 2.

Kazatomprom 2007, Uranium Mining. Kazatomprom web site

IAEA 2002, Country Nuclear Power Profiles

IAEA 2002, Uranium 2001: Resources, Production and Demand (Red Book)

Perera, Judith 2003, Nuclear Power in the Former Soviet Union, vols 1 & 2.

Kazatomprom 2007, Uranium Mining. Kazatomprom web site

If we are buying uranium from another country is there any assuarance that there won't be the same problem we are facing with oil and gas?

ReplyDeleteThirukumaran a/l Ramasamy Chettear

ME083655

thiru_5519@hotmail.com