EXTRACTING NATURAL URANIUM ORE

Having passed all the technical and economic feasibility tests, uranium ore can be mined depending on the deposit's characteristics, using an open-pit mine (quarries), an underground mine or by in-situ recovery. This latter technique is most often used for low or very low concentration mineralizations. Ore can therefore be extracted from some deposits which are a priori unexploitable by traditional techniques. Solutions are implemented in order to guaranteeprotection of staff and of the environment: spray systems, ventilation, etc.

THREE OPERATING CONFIGURATIONS

To extract uranium, it is necessary to access the deposit. This is done by:

- removing the top part of the covering rock, in the case of open-pit mining;

- penetrating tunnels where the ore is located at a depth, as is the case with underground mines;

- drilling, injecting a chemical solution into the ground that recovers the uranium directly, as with in-siturecovery.

Open-pit uranium mines offer the advantage of easy access to the ore: the techniques and machinery used are similar to those used in quarries or on public works sites. These mines can reach a depth ofseveral hundred meters.

Depending on the amount of ore in the ground and its uranium concentration, a mine can be operated for 10 to 50 years.

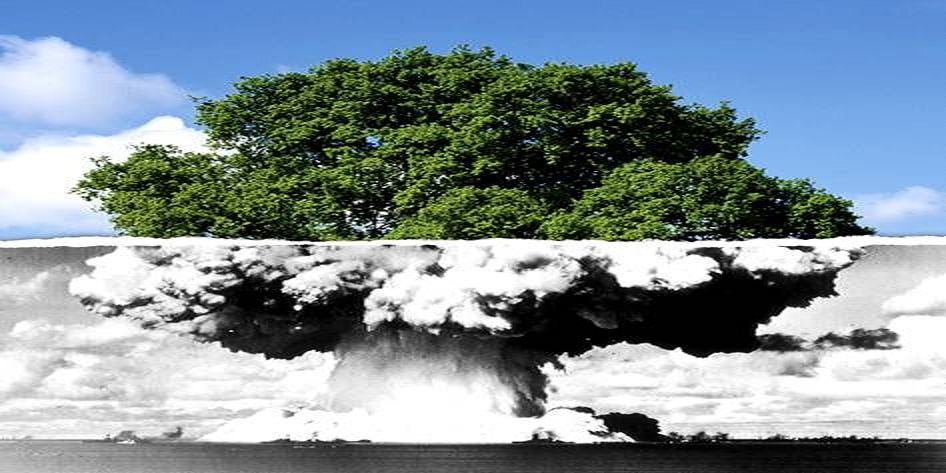

Photograph of the Somaïr open pit mine in Niger

INNOVATIVE TECHNIQUES

AREVA's mining experts regularly test and implement innovative techniques. These improve the performance of existing operations.

The concentration of some Canadian deposits (up to 200 kilograms of uranium per metric ton of ore, as opposed to 10 kilograms elsewhere) has necessitated the implementation of special procedures. Anoriginal method of hydraulic mining was developed for the operation of the Cigar Lake deposit. The ground is frozen using a coolant that circulates in buried pipes. A high-pressure jet of water crumbles the frozen rock, and the ore mixed with water is collected and pumped outside the production zone.Extraction is carried out in a fully automated fashion, and no miners are in contact with this extremely rich ore.

STAFF PROTECTION

The operation of uranium mines can present health risks for miners through the inhalation of radon, a rare gas produced through the disintegration of uranium, along with dust. Effective protection measures reduce these risks: spraying systems cut down on dust, and heavy ventilation is constantly in operation, mainly in underground mining.

In some highly concentrated deposits, operations are performed by remote control, thereby avoiding staff contact with operating zones.

0 comments:

Post a Comment